Add: 21-2#, Xinggang Road, Huangshigang Industrial Zone, Huangshi City, Hubei Province

Tel: 0086-13597667790

Contact: Kate Yan

E-mail: kate@hongxingmold.com

Website: hargravemusicfestival.com

Details

Details

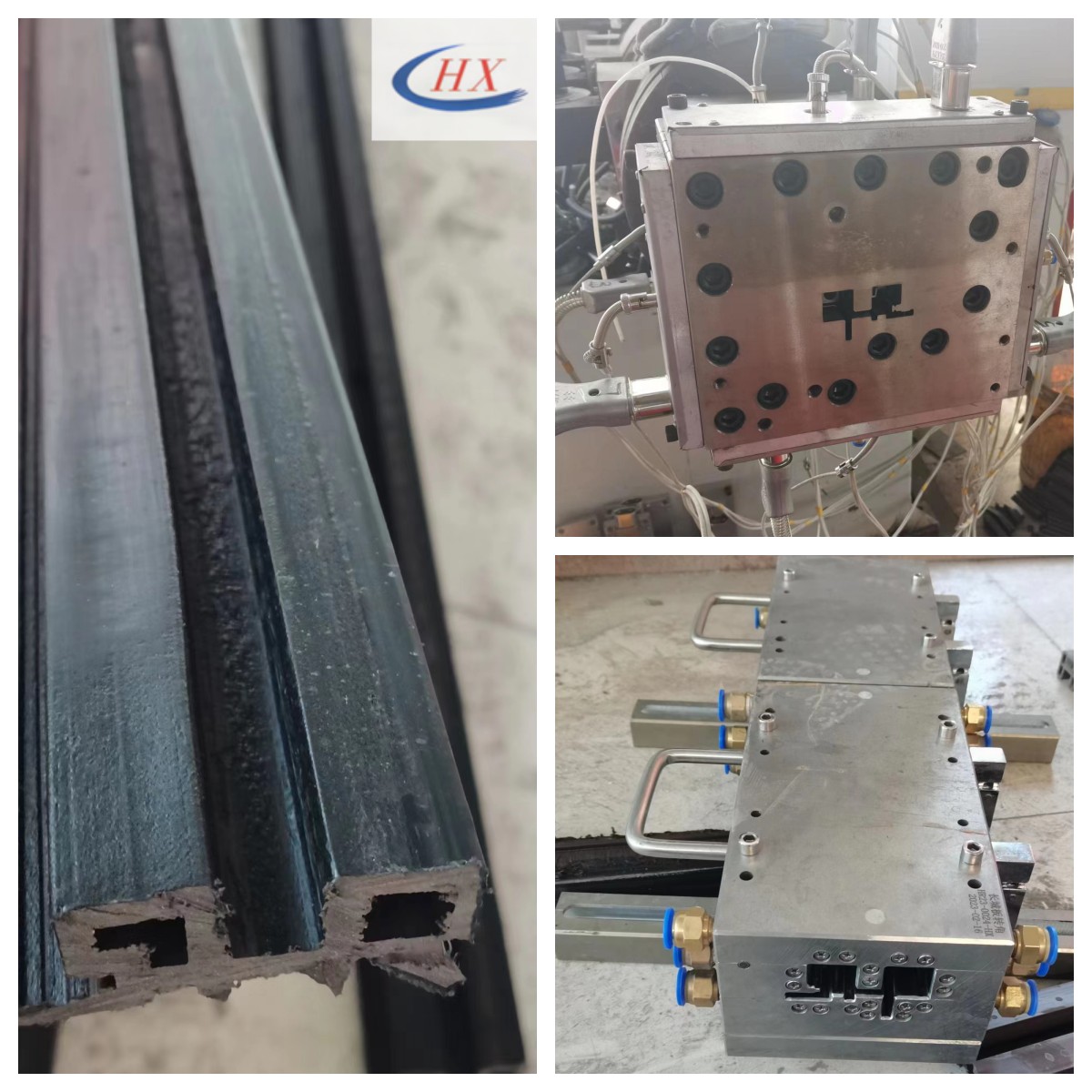

Extrusion is a process for compacting metal. A piston or plunger is used in this procedure to apply a compressive force to the workpiece. A billet or ingot (a metal workpiece of conventional size) is offered initially.

This billet is placed in an extrusion press, heated during hot extrusion, or left at room temperature. The metal is placed in a cylinder and pressed by a piston in the extrusion press, which is similar to a piston-cylinder mechanism. A die is attached to the cylinder’s upper portion.

A plunger installed in the press immediately applies a compressive force to this component, forcing the billet to die. The die is the opening for the required cross-tiny section. The worked metal can flow through the die and take on the desired shape thanks to the solid compressive force. The extruded item is then removed from the press and heated to improve its mechanical qualities.

| [Last] [Next] [Return] |

Order Online

Products that may be of interest

Information